AUTOMOTIVE TAPE FOR COMMERCIAL VEHICLES

Double-sided tapes to assemble wing mirrors,

that bond permanently and withstand all outdoor conditions

These products may have to be applied in cold conditions, and in use they have to withstand freezing cold as well as hot conditions; rain, salt spray and solvents; vibration and impact They also have to conform to OEM and International standards and specifications. They are some of our highest performance products.

-

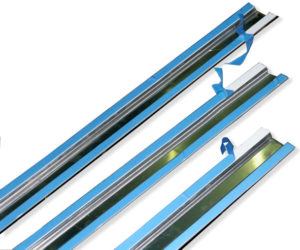

Vehicle roof bonding

We supply double-sided tapes specially developed to bond aluminium and GRP roof skins to metal roof sticks, quickly and effectively.

-

Mirror bonding

Double-sided tapes to assemble wing mirrors, that bond permanently and withstand all outdoor conditions.

-

Other tape applications

- Bonding internal bump strips

- Bonding badges and emblems -

Reflective parts

- Reflective tapes approved to ECE104 that also include your own logo

- Reflective tapes for vehicle graphics and other applications

- Reflective cut and printed parts

Commercial Vehicle Body Building

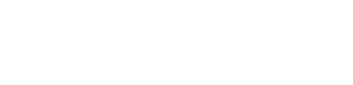

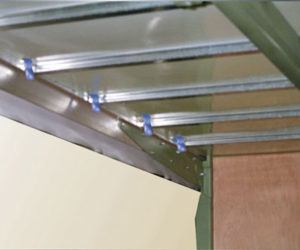

Product: 2mm HTAF bonding tape

Advantages

Film liner slips out easily from any angle, thereby creating the bond between ali roof section and support rail.

FOR EXPERT ADVICE, FREE SAMPLES OR TO ORDER, CALL TECHNIBOND ON +44 1628 642800

CUSTOMER REVIEWS

SWIPE TO SEE MORE TESTIMONIALS

Frequently Asked Questions

We slit most of our products to order, so we have no standard roll width. If you want 13mm or 133mm, you can have it.

As a standard, the minimum is 6mm. We can slit most products narrower than this (we have slit down to 1.6mm) but we charge the same per roll as if it were 6mm, due to the increased slitting and packaging difficulty and the increased waste. The maximum width depends on the product, but is usually at least 1 metre.

We hold large quantities of bulk rolls in stock and manufacture to order. That's the only way we can offer the number of products and product variations that we do.

UK deliveries on rolls, 3 to 5 working days. Spools, pads and die-cuts are 10 working days. If your order is urgent, please speak to our sales department and we'll try to help. Export orders are subject to longer delivery times.

Our MOQ on most rolls is £100. On rolls of Techniflex and on other formats it is £200.

On UK orders over £200 delivery is free. On orders between £100 and £200 we add a small order charge of £20. We can arrange a.m. and courier deliveries for additional charges.

As our products are made to order, we cannot generally accept returns unless the goods are faulty.

We are proud to guarantee the quality and performance of all our products and will quickly provide a replacement or refund if they fail to meet our standards.

Yes, we export around the world. Currently we export to Europe, the Far East, Australia and the US.