Edge Bonding of Resin Filled Glass

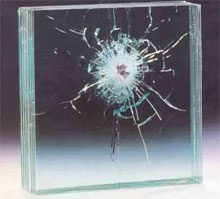

Resin filled laminated glass is ever more becoming the preferred alternative to traditional laminated/security glass.

The traditional method uses a PVB film to bond the two layers of glass together. The PVB film requires a combination of high temperature and pressure to successfully fuse and bond. This production process requires expensive machinery and can only be used on certain thicknesses and grades of glass.

Resin filled laminated glass is manufactured by bonding two sheets of glass together at their edges using glass clear adhesive tape (Techniflex THB), and injecting a liquid polymer between the glass. The polymer is then cured using a catalyst (often UV light). By using a combination of different grades and thicknesses of glass and adhesive, a multitude of bespoke laminated glass formats and sizes can be produced. By laminating several layers together, the glass can even be made bulletproof.

The relatively simply process and low machinery cost make resin filled glass a particularly attractive mode of laminated glass manufacture when compared with the tradition PVB film method.

Techniflex THB is available in 0.5mm, 1mm, 1.5mm, 2mm and 3mm thickness to suit different applications.

Call us for details and pricing on 01628 642800