Techniseal is based on a low cost polymer, but despite that it gives you exceptional sealing performance, is versatile and can last for 20 years or more. And it has some unique properties of its own. An oldie but goodie, it has been supplemented but never replaced by other foams.

What is Techniseal?

It is a PVC foam, coated on one side with an acrylic adhesive, and wound with a paper liner. All three components are important to the product.

PVC foam is based on PVC, plasticizers, and a little colour / filler. The base polymer, PVC, is a remarkable plastic, the third most widely used plastic in the world because of its low cost and great durability. It is nothing like polyethylene and polypropylene because it contains 57% chlorine (and therefore uses less oil to manufacture). The chlorine gives it some unique properties, notably its durability, chemical resistance and low flammability. It is highly resistant to water and oxidation, far more so than steel, and 35 year old PVC pipes have been tested with no reduction of strength. Some of our sealants have also been in use for 20 years or more. PVC is also unique in that it can be plasticized, turning it from a hard plastic to a soft rubbery plastic. Techniseal is a plasticized PVC that has been “blown” during manufacture to form a closed-cell soft foam. The foam provides a good seal against air, water or dust.

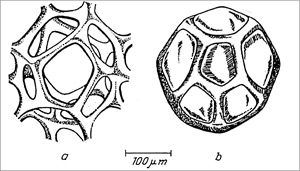

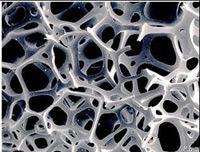

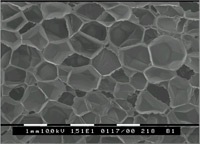

Open and Closed Cells

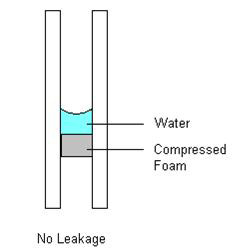

In essence, an open cell foam is like a bath sponge that is porous and will soak up water. A closed cell foam is not porous so water (or air) cannot penetrate it. In the bath, closed cell foam would just bob around on the surface. If you compress an open cell foam you will squeeze the water or air out of it. If you compress a closed call foam, you just compress the air inside the cells (but very high compression can sometimes rupture the cells). So Techniseal is completely waterproof.

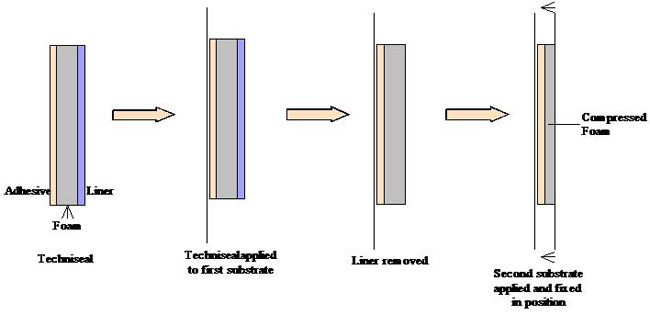

The Adhesive on Techniseal is an acrylic adhesive to resist the plasticizer in the foam, and is provided to locate the foam on the first substrate. It is coated on the open face of the foam, so it is exposed as the roll is unwound. The liner is on the other side of the foam to reinforce the foam, to keep it straight and to prevent it stretching during application. Once the foam is in place the liner is easily peeled off leaving a dry foam face. The foam is located neatly in place.

Contrast this with some of our competitors’ products where the adhesive and liner are on the same side. The liner has to be removed first, leaving a flimsy length of foam that is difficult to apply neatly and without stretching:

Techniseal in use: Four steps to an easy and effective seal:

How does Techniseal work?

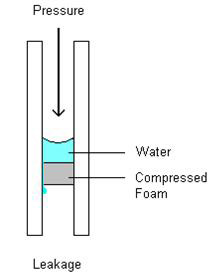

The foam is closed cell, so water or air will never penetrate the foam. Leakage can only occur between the face of the foam, and the material it forms a seal with. That is why compression of 30% is required, to make sure the foam fits tight to the surface and exerts a force on it. If the air or water pressure is high enough, it can force itself past this surface. But it will never go through the foam:

The resistance to leakage, therefore, depends on the pressure the foam exerts on the surface of the material. There is a problem here with many foams, known as compression set (see our later article – understanding performance). Many foams, after being in compression for some time, lose their ability to recover; they are permanently reduced in thickness. So they no longer exert a pressure, and the performance of the seal is greatly reduced. PE foams are particularly bad in this respect; PE may be cheaper sealant but it is a poor sealant.

This also explains why we manufacture Techniseal in different densities. Firmer foams will exert more pressure and provide a better seal. Techniseal 330 will seal against higher pressures than Techniseal 110.

One More Fact

PVC foams have one other unique property, that because it contains plasticizer, the foam does have a slight surface tack. Undetectable, but there. And under long term pressure it will actually bond quite firmly to most surfaces, so the sealing performance improves more and more with time. Most foam sealants become worse with time. Because PVC foams have been around so long they tend to be thought a bit “low tech”. They are actually excellent high performance sealants.

In cases where the joint periodically has to be opened (windows and doors; inspection hatches) this ability to bond is a problem. It is overcome by laminating a polyester film to the dry face of the foam – our Techniseal 220M grade. Some of the sealing performance is unavoidably lost.

Comparison of Techniseal with other foams

Brochures

Brochures

Click to download our latest brochures in Adobe pdf format.