The performance of an adhesive product, whether designed to create a permanent fix or to peel off easily like a Post-it™ note, will be strongly affected by the surface energy of the material to which it is being bonded.

High surface energy levels, found in traditional materials like metal, glass, wood and ceramics, makes them relatively easy for adhesives to deal with. However, many modern synthetic materials offer a much greater challenge because of their low surface energy characteristics.

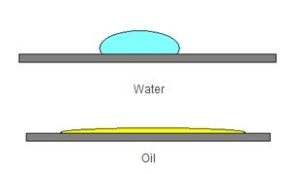

Surface energy, also known as surface tension, is determined by the composition and arrangement of molecules within a material. Take the differences between water and oil, two liquids which, as the saying goes, don’t mix. Water has a high surface energy and will form distinct droplets, whereas low surface energy oil spreads out or wets out on most surfaces. This makes oil an ideal lubricant. Oil derived plastics also have low surface energy characteristics and it is a major achievement of adhesive technologists to have developed products to work effectively with them.

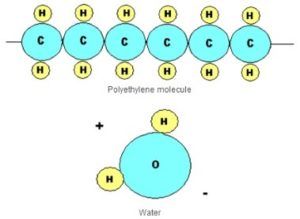

Surface energies are also determined by polarity. For instance, water’s asymmetric molecule will create a higher charge than the symmetric molecule of oil-derived polyethylene. This charge or polarity gives water a high surface energy. Low surface energy materials are sometimes call apolar materials.

Adhesives need to wet out on a surface to form a bond; they wet out easily on high surface energy materials but wet out poorly on low surface energy materials. We develop lower surface energy adhesives to cope with the lower surface energy substrates, by polymer choice and by adding low energy resins and additives. Technibond provide a complete range of adhesive tapes to deal with the specific surface energy demands of different industrial materials. Our Surface Energy Chart gives a few examples:

Download our Surface Energy Chart

Low surface energy materials can offer distinct benefits. For instance, while it is difficult for adhesives to bond to them, it is similarly hard for dirt and contaminants to stick to these surfaces. Their characteristics are therefore used to good effect with easy to clean and self cleaning surfaces as well as anti-graffiti finishes.

The appeal goes further too. Low surface energy materials can be cost-effective and have useful chemical and physical properties. For example:

- Polypropylene has excellent resistance to flexing and, like polyethylene, is economical, solvent resistant and easily moulded and extruded

- EPDM rubber is excellent for weathering as well as for resistance to ozone and some solvents

- Polystyrene has excellent clarity

- Powder coating paints are tough, economical and contain no hazardous solvents

Because of their many advantages, these materials are being increasingly used in all sectors of manufacture. This means challenging times ahead for adhesive technologists!

Our free Surface Energy Chart download will help categorize the adhesive type needed for different materials. You can also send us a sample and we will test it in our laboratory and advise you. Products such as powder coated paints, for example, differ widely between different manufacturers.