We have worked with a number of our customers to develop types of returnable packaging, to avoid the costs and inconvenience of disposing of cardboard cartons. These costs include collection charges, handling costs and the administrative costs of complying with waste packaging regulations.

Early on, we found that it was not practical to return and reuse cardboard cartons. Too much damage was caused, the used cartons did not easily pack flat and required strapping, and the total costs did not balance out. It was cheaper just to throw them away. Fluted plastic board gave similar problems even though they were more expensive. A total re-think was necessary, and we have now implemented two very effective solutions:

- Returnable steel cages

We developed and designed these steel cages especially for the transportation of our bobbins. They fit a standard euro pallet, are stackable and offer superb protection for the contents. The contents are also highly visible.

Each cage holds 48 or 72 bobbins, depending on the bobbin size. We load the bobbins direct from our bobbin machine, saving labour and handling at our end. You take the cage directly to your extrusion machine and load your machine directly from the cage, saving labour at your end. Each cage means 48 or 72 cartons that no longer need to be cut open, unpacked, flattened and taken away. And it saves the disposal costs. The next time we deliver, we simply pick up the empty cage and bring it back.

You can also put the used cores back on the special shafts for return; we examine these and re-use those that are in good condition, saving even more. Of course, there is a cost to transport the bobbins back to us, but that is well within the savings made on carton costs.

Note: we also supply tape applicators for extrusion lines.

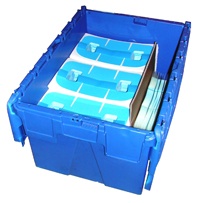

- Blue Green Returnable plastic boxes for die-cuts

We have adapted a common design of reusable plastic box for our die-cut parts. These boxes are extremely robust, offering better protection for the contents than a cardboard carton. They can be opened without the use of sharp cutting tools, and the full boxes are stackable. The empty boxes stack inside one another to take up less space for transportation. And ours are a tasteful shade of blue.

Again, we pack these direct from the machine, saving a separate packaging operation. You simply take the boxes where the product is needed, and flip open the lid. The empties are stacked neatly, and we pick them up with the next delivery. You don’t have to issue knives to cut open taped cartons with the associated health and safety risks. You don’t have to flatten and dispose of cardboard cartons. The boxes are clean, robust and practical.

The cost to us, including return of the boxes, is neutral. To the customer, it saves time and the cost of disposal. And environmentally, studies have shown a much reduced carbon footprint for reusable plastic cartons compared to single drop cardboard cartons. So they’re green. But blue.

The cost to us, including return of the boxes, is neutral. To the customer, it saves time and the cost of disposal. And environmentally, studies have shown a much reduced carbon footprint for reusable plastic cartons compared to single drop cardboard cartons. So they’re green. But blue.